In the high-stakes world of military manufacturing, a single failure can be catastrophic. In fact, it can cost lives, which is why certification in military CNC machining is not optional. CNC machining powers mission-critical components in both the defense and aerospace sectors, and that means there is zero tolerance for failure in these vital military parts.

Here, we will explore why certifications are essential in military CNC machining, how they ensure quality and safety as well as meet regulatory demands, and how MultiSource Manufacturing is fully equipped to meet these critical standards.

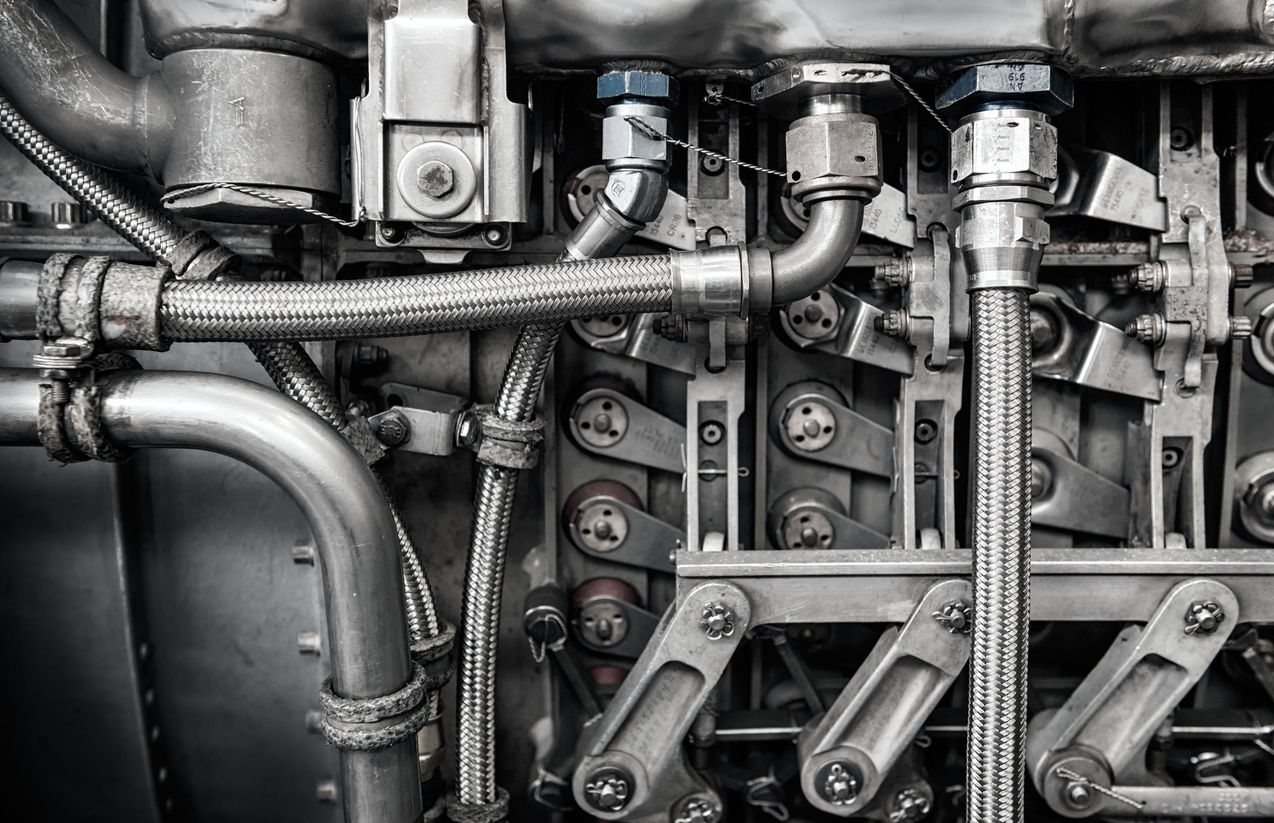

Exploring the Unique Demands of Military and Defense CNC Machining

Military and defense components have high-performance requirements because they must perform in extreme environments involving heat, stress, corrosion, and vibration. That means there is zero margin for dimensional or functional errors. These industries also have strict material sourcing and traceability requirements, and manufacturers must meet stringent DFARS, ITAR, and other standards.

In addition, precision machining manufacturers must fully document every step in the manufacturing process, and certifications are required at every checkpoint. The supply chain must be secure and confidential, protecting sensitive designs, data, and government intellectual property, so precision should be guaranteed at every stage.

A Closer Look at Certifications in Military CNC Machining

Various certifications play important roles in machining for military components. They include:

- AS9100: Tailored for aerospace and defense, this certification ensures rigorous quality management and continuous improvement throughout the entire production process.

- ISO 9001: This certification acts as a foundation for quality systems that ensures consistency, traceability, and expert process control.

- ITAR: The International Traffic in Arms Regulations certification is required for manufacturers that are handling military designs and data, protecting U.S. defense and military technologies.

- DFARS: The Defense Federal Acquisition Regulation Supplement specifies cybersecurity and sourcing requirements, and also enforces supply chain integrity and security.

The Risks of Working with a Non-Certified Machine Shop

When you work with an inexperienced, non-certified manufacturer, you’re risking the entire success of your project. You could experience quality failures and recalls, with greater chances of defects, rework, and delivery failures. Non-compliance with ITAR or DFARS can result in expensive fines or catastrophic legal consequences. With a non-certified manufacturer, you may also experience supply chain disruptions due to missed deadlines, reworks, failed audits, and disqualification by government contractors. As a result, expect consumer loss of trust and a damaged company reputation, risking your entire product line.

How MultiSource Manufacturing Exceeds Certification Standards

MultiSource is certified, compliant, and combat-ready, and we have the certifications to prove it. In addition to our ISO and AS certifications, we are NIST 800-171-compliant, and adhere to important DFARS and ITAR requirements. MultiSource Manufacturing is committed to quality management and operational excellence, as well as secure data and manufacturing processes. Our ITAR-compliant processes allow us to take important cybersecurity measures, and we also offer comprehensive traceability and documentation.

At MultiSource, we have a proven track record of success in the aerospace and defense sectors, and we provide expert precision machining services, which include CNC milling, CNC turning, Swiss machining, wire EDM, secondary processes, and much more. Our team is responsive and dedicated to providing our customers with expert project management and engineering support.

MultiSource can help you stay mission-ready with our fast quotes, prototype-to-production support, compliance documentation, scalable capacity, and dedication to continuous improvement. Certifications are the foundation of trust, performance, and compliance in military CNC machining. From AS9100 to ITAR, we help you simplify your supply chain and deliver mission-critical components with confidence. Reach out to MultiSource Manufacturing today to get started.