Precision milled parts typically have tight tolerances and complex geometry, and are repeatable, making them advantageous components. High-quality precision milled parts matter, and have a large impact on product performance and reliability, as well as safety, efficiency, and more. Let’s take a closer look at some key industries that rely on these parts and how MultiSource Manufacturing stands apart from competitors.

Top Industries That Rely on Precision Milled Parts

Aerospace and Defense

Precision is essential in these critical markets, which require extreme tolerances, weight reduction, and certified traceability. Accuracy is non-negotiable because lives depend on it. Examples of precision milled parts in these industries include aircraft structural components like brackets and frames, engine mounts and housings, and hardware components.

Medical Devices and Healthcare

In the healthcare industry, the slightest deviation can have catastrophic consequences. There is no room for error. Precision is necessary for biocompatibility and regulatory compliance, and micro tolerances are required here. Examples of medical precision milled components include surgical instruments, implants, and diagnostic equipment parts.

Industrial Machinery and Equipment

The industrial market requires strength. Precision is necessary to withstand rough conditions and increase durability and stability. Examples here include pumps and valves, robotics and automation components, tooling and fixtures.

Semiconductor Industry

Here, miniaturization is common so precision is essential, as well as electrical compatibility and thermal control. Reliability is key, as well as meeting exacting standards. Precision milled parts in this market include housings for sensitive components, connectors, and precision enclosures for data systems.

No matter the industry, you can expect certain challenges that only the precision milling process can solve. This method offers enhanced precision quality and consistency, as well as the ability to manage tolerances across batches and reduce scrap and rework. Precision milling also prioritizes speed to market, as well as shorter lead times without sacrificing quality. Another key challenge is balancing precision with cost efficiency but milling services can alleviate that cost pressure by reducing material waste and accelerating production timelines. Additionally, you can expect better supply chain reliability, scalable production, and on-time delivery.

How MultiSource Manufacturing Stands Apart With Precision Milled Parts

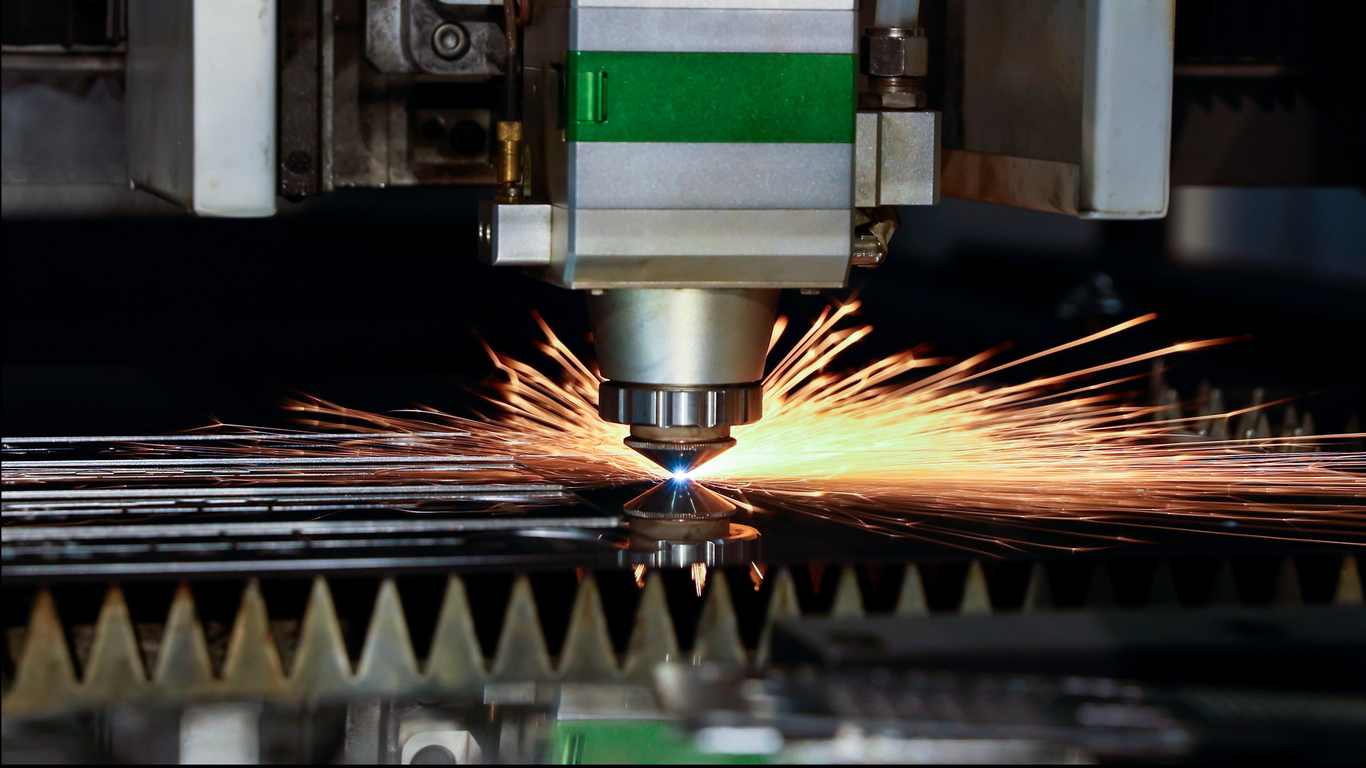

At MultiSource Manufacturing, our specialized CNC machining capabilities are extensive, allowing us to serve a variety of industries with expert care. Our precise CNC milling services enhance accuracy and performance, and we use a range of advanced 3-, 4-, and 5-axis milling machines that are ideal for your low- or high-volume production needs.

Quality is our core focus, and we hold a variety of certifications, including ISO 9001:2015, ISO 13485:2016, and AS9100 D, all of which hold us to a higher standard of excellence. MultiSource offers customer-centric production, including DFM support, prototyping to full production capability, and flexible batch sizing.

With our supply chain strength, on-time delivery performance, and energy-efficient operations, partnering with MultiSource means that your every precision need will be met. Get in touch with our team today to learn more about how we can craft precision milled parts for your next project.