In mission-critical industries like aerospace and defense, meticulous attention to detail isn’t just beneficial — it’s an absolute requirement. Precision machined components are utilized in crucial applications within these industries, and there is no room for error. Accuracy and quality play a vital role in high-performance precision metal machining, and partnering with an expert precision metal manufacturing is the most important decision you can make for the success of your project. Let’s take a closer look at why these factors matter in critical applications.

What is Precision Metal Machining?

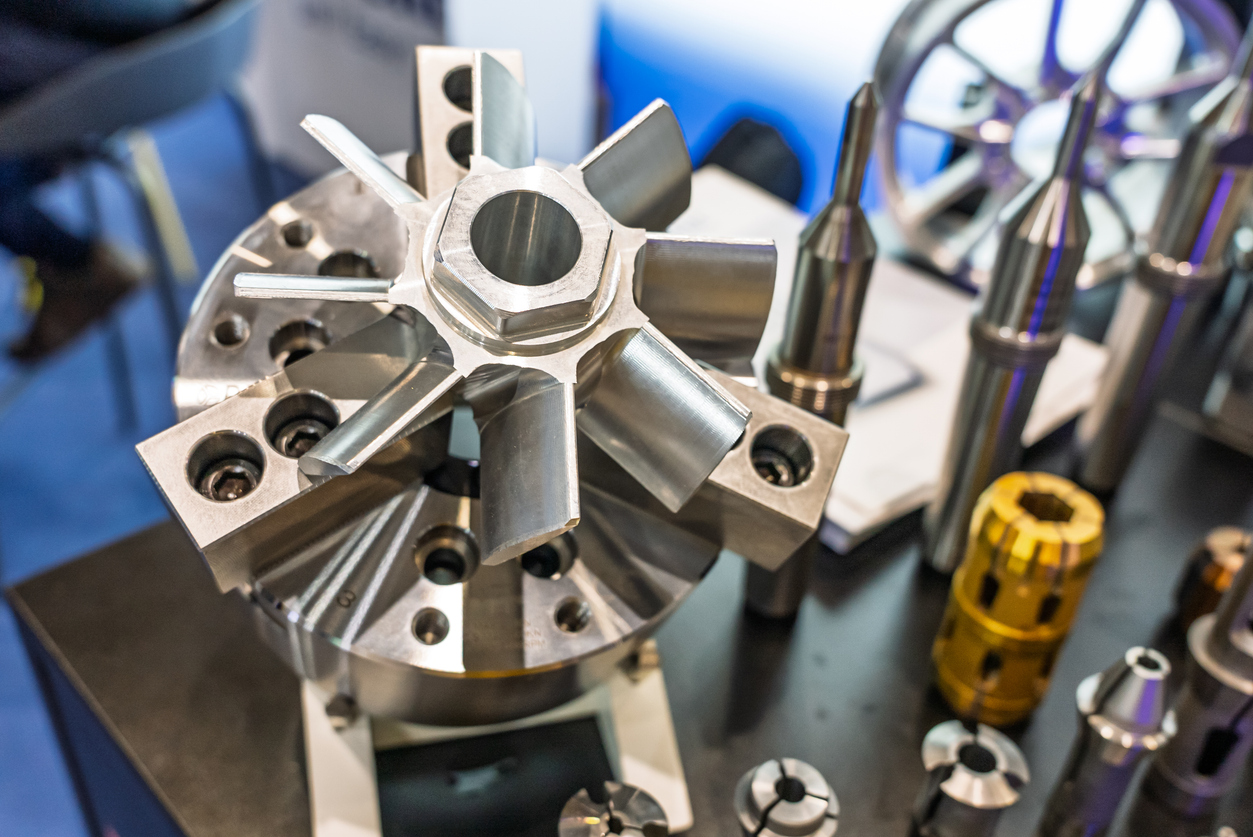

Various manufacturing methods are ideal for precision metal machining, including CNC milling, CNC turning, Swiss machining, and wire EDM, each of which are well-suited for crafting accurate and reliable components. Even more advantageous is that these manufacturing processes are versatile and can be used with a variety of different materials, such as aluminum, stainless steel, and titanium.

In critical applications, precision is non-negotiable. In the aerospace industry, accuracy is required to ensure safety during aircraft operations. Similarly, weapons systems and military equipment require reliability in the defense industry, while precision is vital in the medical market in order to improve patient outcomes. Other important commercial industries, such as electronics or automotive, require precision. Accurate dimensions must be met, which impacts overall performance, as well as durability, surface finish, and reliability.

Here, precision is mandatory. Risks of poor accuracy and quality are serious, and include:

- Equipment failure

- Poor performance

- Safety risks

- Increased costs due to reworks

All of these risks can have a devastating impact on the manufacturer’s reputation, and that kind of damage can be difficult to overcome. Customers value reliability, and precision significantly contributes to the production of consistent, quality components.

How MultiSource Manufacturing Ensures Precision and Quality

When it comes to your precision metal machining, you deserve the best, which is why partnering with MultiSource Manufacturing is a smart choice. For over 50 years, we’ve been an industry leader in the machining world and we’re prepared to offer you top-tier services. Our capabilities include CNC milling, CNC turning, Swiss machining, and much more. In addition, you can trust our start-to-finish support, like our complex grinding or fine finishing services, which ensure your project is completed to your exact specifications.

We’ve also provided critical industries with precision metal machining, so we’re well-equipped to craft the key components your project requires. Our customers are always top of mind, and we’re committed to supporting your project however we can, whether that is through design and engineering support, expert production, or comprehensive secondary processes. If you have a precision metal problem, we have solutions.

Excellence is part of our foundation at MultiSource, and we have the certifications to prove it. In addition to our ISO and AS certifications, we are also NIST 800-171-compliant and adhere to DFARS and ITAR requirements. Our skilled team of precision machining experts operate under tight quality control procedures, and we invest in advanced machinery that allows us to increase efficiency and reliability.

We’re eager to ensure your critical application meets success. Turn to MultiSource Manufacturing for exceptional precision metal machining today.