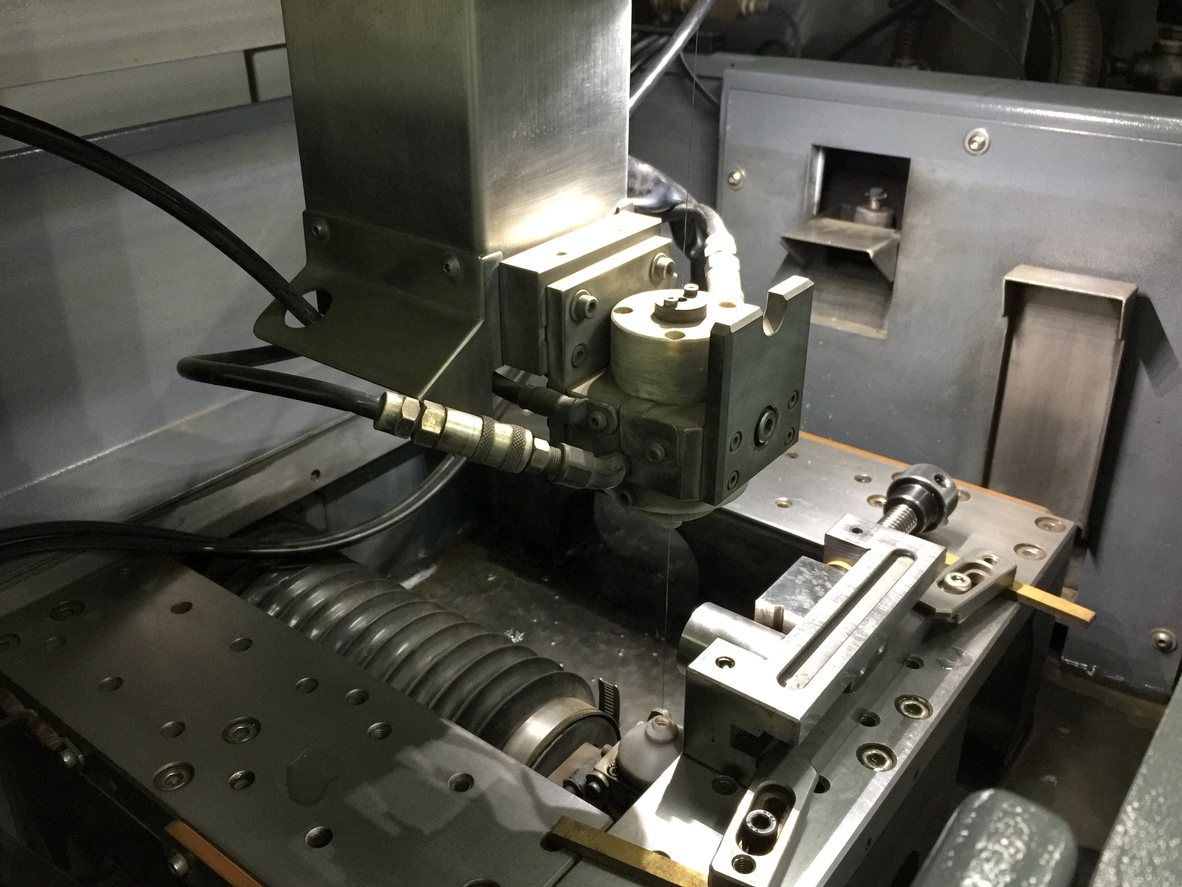

In mission-critical industries like aerospace, medical, or defense, it’s crucial to achieve tight tolerances, but it can be difficult to deliver this level of precision. That’s why wire EDM (electrical discharge machining) is such an effective machining method. This technique involves non-contact cutting using a very thin wire that is electrically charged. These services are ideal for parts with complex geometries or tight-tolerance components and offer unique advantages for high-precision machining.

Here are 5 key reasons to consider wire EDM services and how MultiSource Manufacturing can support your next project.

Reason #1: Unmatched Precision for Complex Geometries

Wire EDM services can offer extremely tight tolerances (+/- 0.0001” or better), making it ideal for components with intricate designs, fine details, or sharp/difficult to machine internal corners. Some examples here include medical implants, turbine blades used in the aerospace industry, and other components with complex geometries needed in mission-critical applications.

Reason #2: Ability to Work with Difficult Materials

Wire EDM equipment can cut materials that are too difficult to machine using traditional methods, such as inconel, titanium, and more. With this process, there is no need for pre-heat treatment or softening, which reduces overall steps during production and allows your project to meet the market faster. This method is useful in industries that require durable materials, such as defense, semiconductor, and aerospace.

Reason #3: No Mechanical Stress or Tool Pressure

Because wire EDM is a non-contact process, you don’t have to worry about tool deformation or warping. This maintains the integrity of delicate components, making this process well-suited for prototypes and finished parts with demanding tolerances.

Reason #4: Superior Surface Finish Quality

Wire EDM services achieve excellent surface finishes, reducing the need for additional finishing services. This is highly important in medical components where surface quality affects performance.

Reason #5: Highly Repeatable Automated Processes

With CNC-controlled wire EDM services, you can expect consistent and repeatable results, which is beneficial for high-volume production. Operating “lights-out” increases efficiency and output, making this process ideal for scalable production.

Trust MultiSource with Expert Wire EDM Services

MultiSource Manufacturing understands the benefits of wire EDM services, and we employ high-tech, high-speed solutions for affordable and reliable components. We are able to handle larger workpieces and complex geometries, and can work with a variety of different materials, especially ones that are hard to cut.

Our customer-centric process includes our engineering support for DFM, prototyping services, and efficient production for faster turnaround. In addition to our wire EDM services, we also offer CNC milling, CNC turning, Swiss machining, and more. We take your project from start to finish with our expert assembly and secondary processes.

At MultiSource, we’re here to raise the standard of your components. Connect with us today to learn why our wire EDM services are ideal for high-precision parts.